How to prevent airborne dust by increasing air humidity

Dust can come from a wide variety of sources – from the processing of raw materials such as wood or plastics to microscopic fibres and dirt particles.

The problems of airborne dust in a production environment are obvious: Risk of lung disease in humans and risk of equipment failing when tiny dust particles enter motors and electronic components, causing overheating or the build-up of static charges.

Airborne dust can be flammable and can constitute a danger of explosion in industries such as mining, iron casting, wood and even food production. Dust is a risk to be taken seriously.

Defining dust

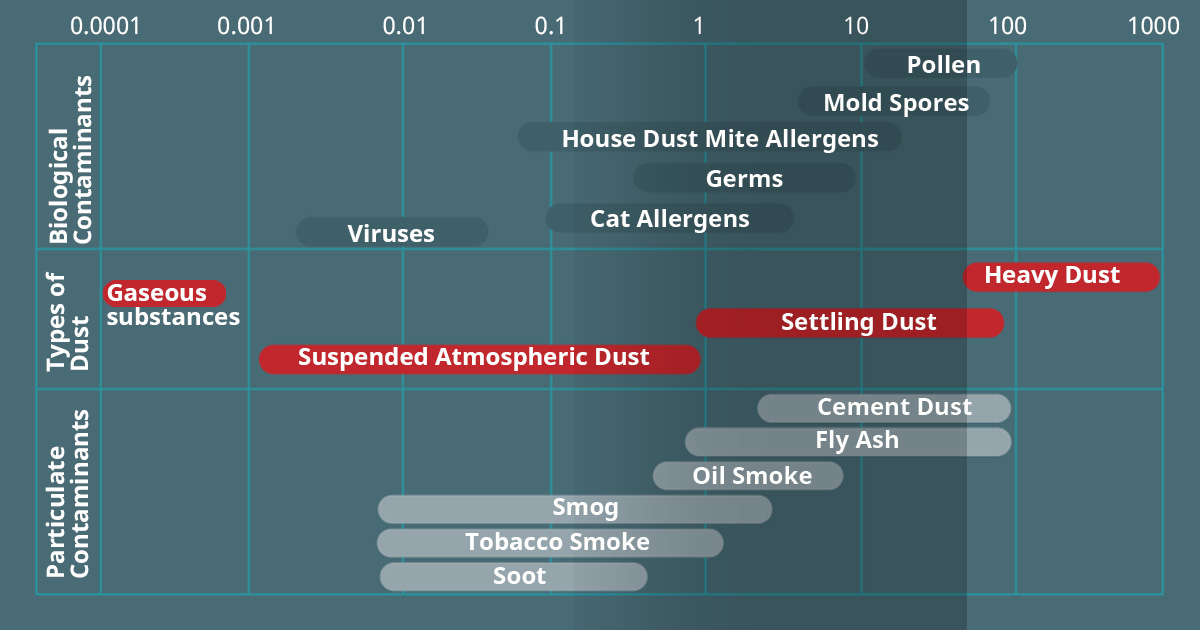

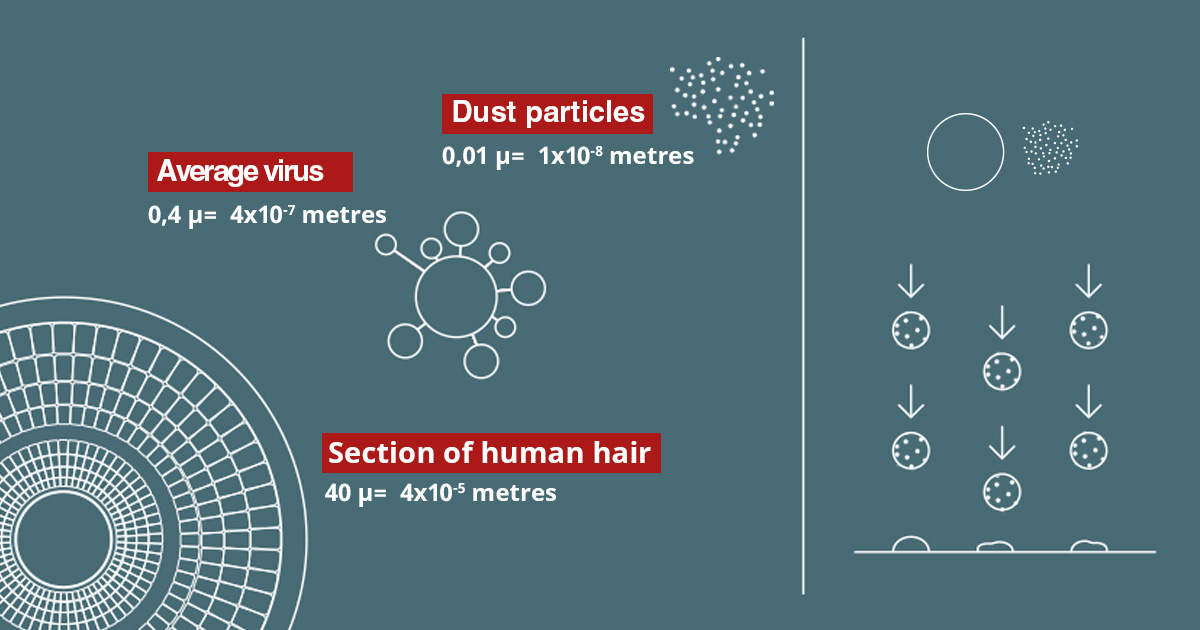

A dust particle or fibre suspended in air can be anything from 1 mm in diameter down to 0.01 micron or 1×10−8 meters. Below this level, by definition anything airborne is no longer dust, but a gaseous substance.

Larger-grained dust will tend to settle by gravity close to its source, but finer-grained dust can be much harder to control.

Definition of dustDust particles come in many sizes. Only high-pressure air humidifying systems can produce water mist fine enough to capture the smallest dust particles. Cement dust, for instance, which is a real health hazard to humans, has a particle size between 10 and 100 microns and will be perceived as a fine-grained, visible dust that settles on surfaces as a layer. Soot (and tobacco smoke) has a particle size as low as 0.01 microns – dust this fine will not settle by gravity but will remain suspended in the air indefinitely. |

Gravity assistAirborne dust can be incredibly fine-grained; soot and several types of smoke are smaller in particle size than most viruses. Only by controlling the size of the water mist particles is it possible to ensure that dust is captured in water |

There are several technologies available to alleviate the risks related to airborne dust. The most common are:

- Containment of production processes

- Exhaust ventilation

- Air purification technology

- Air humidifying systems

These technologies often go hand in hand - at Airtec®, our project engineers often work in close collaboration with suppliers of ventilation and air purification technology to design the optimum dust mitigation solution for a production facility.

Case in point: Saw dustOne typical example of airborne dust that causes problems is saw dust. Dust from wood production is classified as a carcinogen, i.e. a cancer-causing substance, and can have a particle size as low as 0.5 micron – but it is practically impossible to prevent saw dust from being formed and propagated in sawmills or furniture production. Furthermore, airborne saw dust is highly flammable and can burst into explosive fire by sparks or even by high temperatures. |

Contain and collect using water

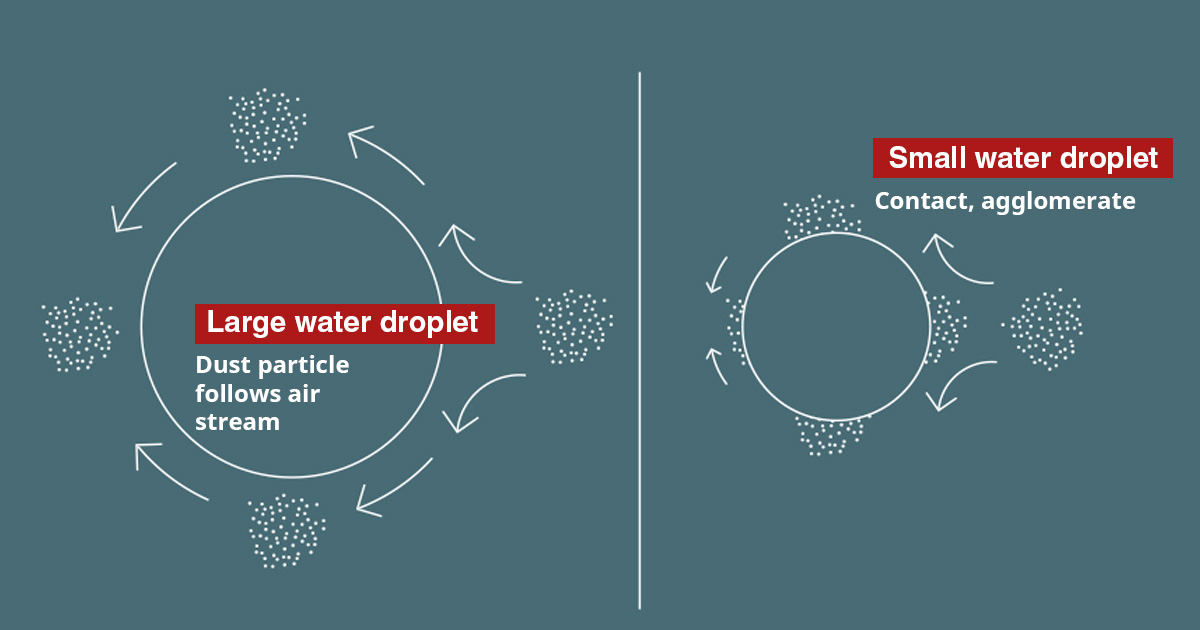

By systematically installing nozzles at strategic points within the production facility, it is possible to contain and collect airborne dust using water vapor. Each individual water droplet can absorb dust particles and fibers from the air, gradually both encasing the dust and allowing it to fall to the ground – effectively removing the dust from the air.

An Airtec® system will produce a very fine water vapor spray at a pressure of 50 bar.

Spray nozzles are installed at the correct location and distance to product equipment to obtain optimum dust control without causing condensation to form on equipment and raw materials. Various nozzle sizes make it possible to adjust the size of the water droplets, as this is a critical factor in dust collection. This is why we always make a thorough investigation of the precise requirements before designing a solution.

At the same time, an air humidifying system will help reduce the adverse effects of excess heat that often arise in manufacturing of several types of products.

Fine mistThe size of water droplets is a crucial factor in their ability to absorb dust particles. |

Making production environments more productive by controlling airborne dust

Controlling airborne dust is a complex matter, where the right solution depends on a number of factors: The type of material used in the production (e.g. wood, cement, plastics, food items etc), the local weather and temperature conditions, previous installations of ventilation or air purification equipment, the factory layout and much else besides.

A collaboration with Airtec® often begins with a Site Assessment, where we do a detailed study onsite in order to come up with practical recommendations.

If you work as a consulting engineer, our team of project engineers can assist in a new project in the design and layout of the solution.

A typical installation from Airtec® will consist of a HydroSens™ control/pump unit fitted on the water intake in connection with a water filter and a reverse osmosis demineralization unit (RO). A number of vaporizers or nozzles such as HydroOne™ or HydroTrio™ are then installed across one or several individually controllable zones within the facility. Using our SCADA software, it is possible to monitor and control the system remotely and to provide documentation, if needed.

See how we’ve done it for others

Airtec® has decades of experience in planning, installing and servicing this type of air humidifying system – take a look at our case stories here.