How controlling humidity levels increases productivity

It is important to control the temperature and the air humidity in the packaging industry to ensure perfect production runs. Hygroscopic material is sensitive to humidity fluctuations, but by controlling air humidity, you ensure a consistent product, fewer production stops, and avoid damaged products and static electricity. Here's how.

In packaging, Airtec® technology can improve productivity in three ways:

- We can help producers in the packaging industry supply a consistent product to the quality specifications of their customers

- Facilities that utilize cardboard, paper, or plastic get a consistent packaging process by using air humidity solutions by avoiding issues caused by inaccurate humidity levels

- The adiabatic cooling effect is highly cost-effective in comparison with traditional cooling methods

Cardboard products, like paper, are hygroscopic in their nature. This makes cardboard products sensitive to fluctuations in air humidity and temperature. Depending on the ambient humidity level, cardboard products will absorb moisture from the ambient air and release it back again, which will cause the product to expand, contract, or wrinkle.

Ultimately, failing to provide the optimal humidity and temperature level affects product quality and can cause production stops in a packaging production.

Examples of issues related to incorrect air humidity

- Damaged and inconsistent products that fail to comply with specifications

- Production stops and downtime

- Static build-up and risk of electrostatic discharge (ESD)

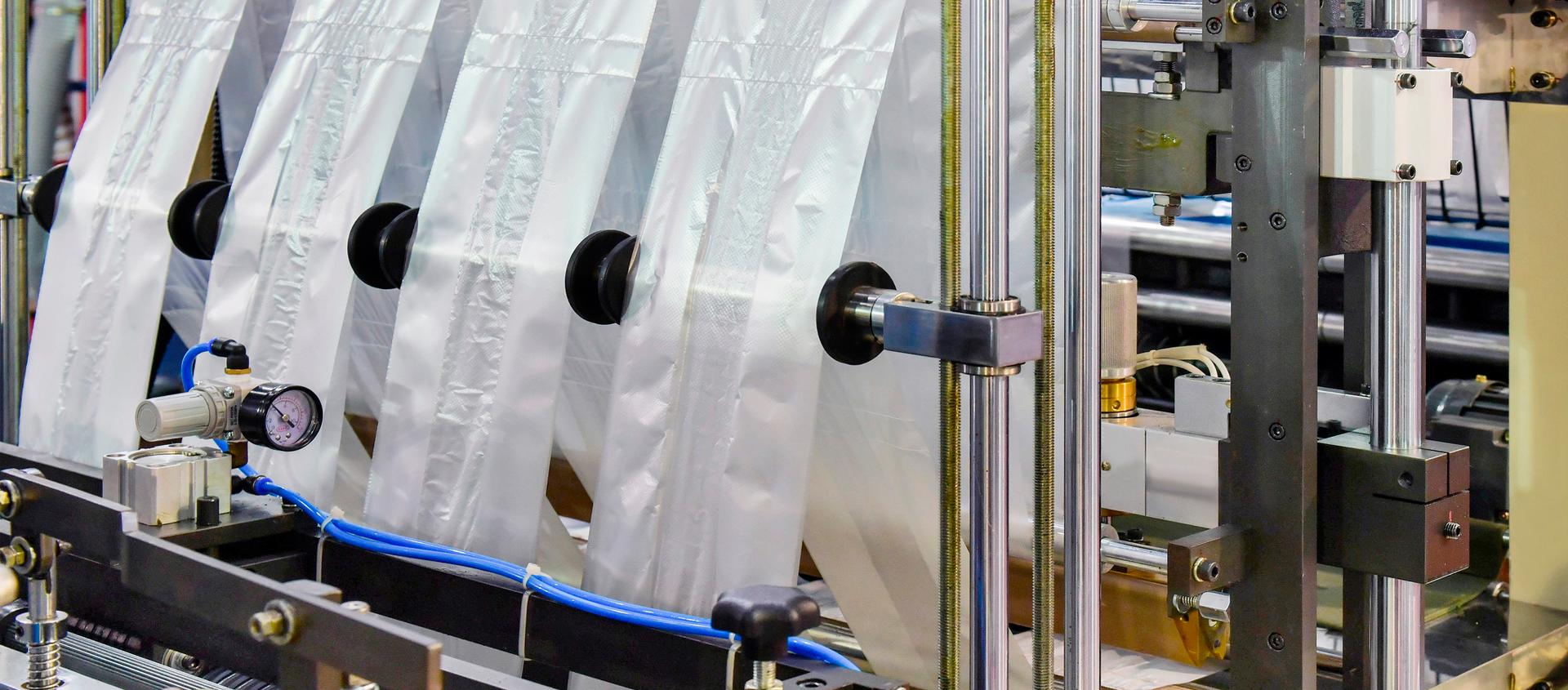

In the production of plastic film or foil for packaging, producers are often faced with the demand of presenting documentation for voltage generated during the production phase.

The installation and continued service of an air humidifying system are vital parts of this documentation effort, and Airtec's expertise and knowhow can be valuable in this regard.

Temperature fluctuations and varying air humidity

Processes in the packaging industry generate high levels of heat, which affects air humidity. Airtec's knowledge and technology enable you to extract surplus heat from the environment, leading to better temperature control and a reduction in static electricity all at once.

Poor control of the air humidity level causes build-up of static electricity and makes individual sheets of cardboard adhere to each other. This leads to poor printing performance or even downtime in printing presses.

Static electricity in rolls of foil will also cause difficulties when different layers of the material will tend to cling together.

To ensure a productive environment with an efficient packaging operation it is vital to maintain optimum production conditions through a constant control of air humidity and temperature.

This can easily be achieved with the know-how and experience built into every Airtec® air humidifying system.

Contact us today and find out more